Blogs

- Aug 24, 2023

- Blog

- HAPS

Successfully Developed All-Solid-State Batteries with High Specific Energy Density

- Achieving Specific Energy Density of 300Wh/kg -

#Next-Generation Battery

Scroll

1. SoftBank is Aiming for Battery with High Specific Energy Density

SoftBank has been developing high specific energy density (Wh/kg) and lightweight next-generation batteries for devices requiring weight reduction such as drones and High Altitude Platform Station (HAPS).

(Ref. https://www.softbank.jp/en/corp/technology/research/story-event/007/ )

In 2020, SoftBank achieved the world's first verification of 450Wh/kg using Lithium Metal Batteries (LMB).

In the following year, we further succeeded in achieving verification of 520Wh/kg, exceeding our previous accomplishment.

In general, it is difficult to be compatible with weight-specific energy density and lifetime characteristics at the same time, especially for next-generation batteries. Lithium metal anode used in LMB is expected to increase approximately ten times capacity (3681 mAh/g) as much as that of graphite anode (381 mAh/g) used in the current lithium-ion batteries, but there are critical issues such as decomposition of electrolyte, large expansion and shrinkage on lithium anode during charging/discharging, capacity degradation and short circuit caused by lithium dendritic growth. As a result, LMB lifetime characteristics are shorter than those of lithium-ion batteries.

To solve these issues, more stable electrolyte is needed. Recently, along with the rapid progress of solid electrolyte, there is an interest about all-solid-state batteries (ASSB) of high specific energy density using lithium metal as anode.

2. About ASSB

All-solidification is a technology to improve the safety, output and other characteristics of lithium-ion batteries. Generally, in batteries, an ion conductor called electrolyte is placed between cathode and anode to transport ions through the electrolyte. ASSB does not use a burnable organic liquid electrolyte, but only a stable solid electrolyte. Since solid electrolyte has thermal stability and high voltage stability, it is possible to suppress the ignition and explosion of the liquid electrolyte due to the temperature rise of the battery. This characteristic can make it possible to use positive electrode materials that exhibit high capacity or high voltage. That’s why we are considering that high safety batteries with high specific energy density are achievable in ASSB.

In addition, some solid electrolytes have recently been discovered to have superior characteristics to liquid electrolyte in terms of chemical stability, stability in low and high temperature environments, and ionic conductivity. These discoveries have increased the feasibility of ASSB to achieve longer lifetime, a wider operating temperature range, and higher output characteristics. Therefore, many research institutes and companies are conducting research and development for all-solid-state batteries.

In the media, terms like “all-solid-state battery,” “solid-state battery,” and “quasi-solid-state battery” (hereinafter referred to as solid-state battery) are often confused or used interchangeably, however, all-solid-state battery is different from solid-state-battery. Solid-state battery is a hybrid system with solid electrolyte and liquid electrolyte. While addition of organic liquid electrolyte promotes early commercialization of the battery, there are no advantages in range of the operating temperature, voltage and lifetime improvement, compared to all-solid-state batteries. As mentioned above, SoftBank aims for the development of ASSB.

Fig.1 Lithium-ion battery and ASSB

3. Challenging Issue of ASSB

While expectations for ASSB are growing, there are many issues. One of the critical issues is to form a good interface between solid particles and to maintain the interface by following volume expansion and shrinkage of the lithium metal anode. Since liquid electrolyte has fluidity, it is possible to form the suitable interface to cathode active material with a complicated and bumpy surface. In solid electrolyte, on the other hand, adequate ionic conduction is not ensured if solid electrolyte (solid particles) and cathode active material (solid particles) do not adhere well to each other. If the interface is not well controlled, the interface resistance will increase, resulting in reduced battery capacity, output, and compromised lifespan characteristics.

In case of negative electrode interface, if control of the lithium metal anode is insufficient, lithium dendrites have been reported to grow along the grain boundaries of the solid electrolyte layer, resulting in a short circuit between the cathode and the anode in early stages. This would cause the battery to heat up and/or shorten its lifetime.

To address these issues, SoftBank is developing some technologies such as a thin coating of a solid electrolyte on the surface of a cathode active material, a nano-order artificial coating on the surface of lithium metal, and an effective compression method of cells in the battery pack. We have successfully confirmed that several technologies are effective in addressing these issues.

4. Achieving to 300Wh/kg and Our Future Challenges

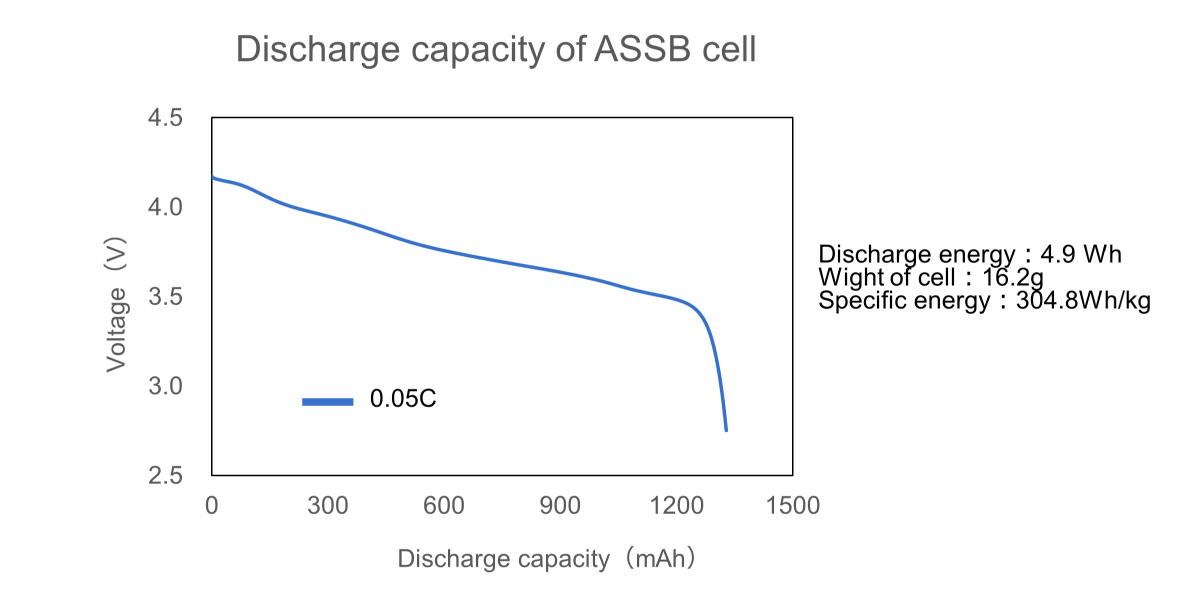

Through joint research, SoftBank and Enpower Japan, a subsidiary of US company Enpower Greentech Inc. have succeeded in the establishment of a control technologies for the interface between cathode layer and solid electrolyte layer by considering a selection of solid electrolyte material, optimizations of compositions of cathode active material and solid electrolyte, the method and materials of cathode coating, and battery production process. Both companies also successfully developed the weight reduction technologies: reduction of weight ratio of solid electrolyte including cathode mixture layer, thinning of solid electrolyte layer and achieved the improvement of ASSB cell specific energy density to 300Wh/kg. This energy value is the same as the maximum value of a lithium-ion battery cell.

Fig.2 Specification of ASSB cell

Fig.3 Discharge capacity of ASSB cell

In the future, we will further improve the capacity density of ASSB by optimizing these technologies. Additionally, we will work on improving cycle performance, reducing operating temperatures, and operating at higher voltages, aiming for ASSB of 400Wh/kg or more with a long lifetime and high output power characteristics.