Robots are increasingly taking on tasks once reserved exclusively for humans. Recognizing this trend, in September 2025 SoftBank Corp. (TOKYO: 9434) announced it developed a new “robot-friendly” server rack with a cable-less architecture that allows robots to install or replace a server simply by pushing it into place.

What exactly makes this new type of rack robot-friendly? SoftBank News spoke with a project leader to find out more.

Michiyuki Otaka

Cloud Infrastructure Development Department

Telco Cloud Development Division

Unified Cloud & Platform Division

SoftBank Corp.

A next-generation server rack that eliminates manual cable work, enabling data center automation

What’s the role of a server rack?

A server rack is a storage shelf used in data centers to efficiently house servers and organize power and network cables. By stacking multiple servers vertically, it enables high-density storage and maximizes processing capacity within a limited space.

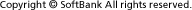

A typical server rack

Our newly developed rack, on the other hand, is designed to accelerate data center automation. Without using cables, it enables automatic electrical and network connections. Since no manual cabling work is required, a robot only needs to push a server into a rack for installation or replacement to complete the task.

Creating an environment where robots can safely perform human tasks

What led to the development of a robot-friendly server rack?

Most existing server racks require manual tasks, such as plugging and unplugging cables, replacing servers and so on. At the same time, the spread of generative AI is driving rapid growth in the number of servers and installation frequency. On top of that, the shortage of skilled technicians and rising labor costs have become major challenges. At large-scale data centers, construction and maintenance can cost hundreds of millions of yen annually.

So you’re saying that relying just on human labor to install and maintain servers is difficult given the explosive growth of generative AI?

Exactly. Server expansion and replacement still depend heavily on manual processes such as cable wiring, labeling and memory installation. With the industry facing a severe labor shortage, shifting these tasks from humans to robots—and building a fully automated data center—was our motivation behind developing this robot-friendly rack.

How did you begin developing this new type of server rack?

One of the biggest obstacles to automation in data centers is the cables themselves. Even if installation is automated, densely packed power and network cables inside a rack hinder robot movement. To fundamentally solve this issue, we aimed to remove cables entirely. Our goal was to create an environment where robots can work safely and with precision.

Conceptual image of a robot-automated data center

How did you achieve cable-less connections for power and networking?

We integrated three elements—power, networking and cooling—into a single server adapter, enabling cable-less connectivity.

For electrical power, instead of using traditional cables, we utilize metal contact components called busbar clips and a power busbar that distributes electricity. Robots simply push the server into place, and power is supplied quickly and reliably.

For networking, we adopted a highly reliable blind-mate optical connector resistant to positional misalignment. It connects to network equipment available on the market via a network busbar to eliminate complex manual wiring.

Cooling also uses a blind-mate liquid-cooling connector, enabling automatic attachment to a manifold without the need for sensor-based checks.

By equipping each element with its own dedicated connection mechanism, we achieved reliable, cable-less automated connections. This is making it possible for robots to operate servers safely and efficiently.

Additionally, the rack incorporates a floating structure that guides the server adapter into place. Even with minor alignment deviations, a secure connection is achieved, accommodating the precise movements of robots.

What challenges did you face during the development stage?

As a data center operator, SoftBank traditionally purchased equipment manufactured by vendors. But existing products on the market couldn’t support full automation. When we asked manufacturers about developing a new rack, we learned that installing standard 19-inch EIA servers with robots would require a special server adapter and rack.

So we designed a system aligned with the Open Compute Project (OCP)’s ORV3 specification—an industry standard for data center hardware—while incorporating proprietary elements. After working closely with partner manufacturers, we completed the current rack design.

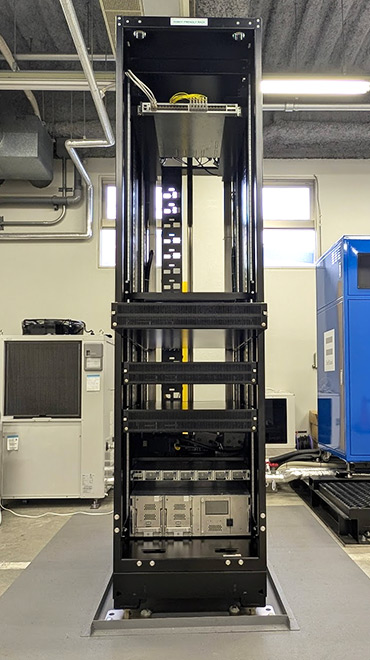

The highly versatile, cable-less rack enables installation of 19-inch EIA standard servers and is compatible with commercial models

How do robots install or replace a server?

We optimized both the physical structure and interfaces for robotic operation. For example, servers connect automatically when pushed in, and the rack structure ensures a straight, unobstructed path between racks. Our design anticipates collaboration with automated guided forklifts (AGFs) and container robots (CTUs).

A lifter robot receives the server from a CTU, then uses QR-code recognition via camera and laser-based positioning to place the server accurately in the specified slot.

Servers and racks can be extremely heavy. What safety measures are built in for robotic operation?

We’ve incorporated Light Detection and Ranging (LiDAR) sensors for obstacle detection, collision-prevention bars, and emergency stop switches. If the robot detects an obstacle while moving, it automatically slows down or stops to avoid collisions with people or equipment.

Testing to begin at “Hokkaido Tomakomai AI Data Center,” a key hub for next-generation social infrastructure

Rendering of the “Hokkaido Tomakomai AI Data Center”

The new rack will be tested at the “Hokkaido Tomakomai AI Data Center” that’s now under construction. What will you be checking?

We’ll evaluate the reliability and connection stability of both the robot-friendly racks and the robots transporting servers. Over the next couple of months, we’ll also verify robot fleet management, robot-to-robot coordination, and interface compatibility with automated systems in preparation for large-scale robot deployment.

Are there plans to expand deployment of the robot-friendly server rack to other locations?

Based on the results from Tomakomai, we plan to standardize the rack design and eventually roll it out to SoftBank’s other data centers. Our ultimate goal is to realize data centers powered by robots and AI that operate autonomously, without human intervention.

Related Articles

(Posted on December 15, 2025)

by SoftBank News Editors