As climate change continues to intensify, achieving Net Zero emissions represents not only a goal, but an essential step toward achieving a sustainable future for humanity and the planet.

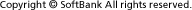

As many companies around the world work to address climate change, SoftBank Corp. (TOKYO: 9434) set its own “Carbon Neutral 2030” target in 2021 and one for “Net Zero for 2050” in 2022. In 2023, SoftBank expanded its scope for Net Zero to its group companies as well.

Achieving Net Zero emissions across the entire supply chain is one important aspect of SoftBank’s Net Zero target. An employee at SoftBank’s Procurement Division, Hitomi Sato, explained how this is being done in practice.

Hitomi Sato

Group Synergy Promotion Department, Procurement Division

FP&A and Procurement Division, Finance Unit, SoftBank Corp.

After handling negotiations with suppliers and managing them as a buyer, Sato has been responsible for promoting supply chain sustainability since 2020. Having a long-time personal interest in ESG through her volunteer activities, Sato describes her current post as a “perfect fit.”

Procurement Division’s activities to realize a sustainable society

SoftBank's Scope 3 emissions (i.e., the emissions of other companies related to SoftBank’s business activities) have a large amount of emissions relative to Scope 1 and 2. This means we can’t achieve Net Zero without the cooperation of our suppliers. So it’s essential for the Procurement Division, which is responsible for SoftBank's supply chain management, to work together with departments promoting environmental measures to address this issue.

Shifting focus from efficiency to ESG

When procuring the materials, equipment, and services needed for business activities, companies select suppliers, negotiate prices and conditions, place orders, and manage individual transactions and the suppliers themselves. At SoftBank, the Procurement Division handles this series of buyer operations, and in collaboration with front-line employees and suppliers, aims to negotiate transactions that are optimal for all parties.

In the past, the mainstream approach to evaluating suppliers' financial performance from the perspective of business viability was to use the QCD (Quality, Cost, Delivery) index, but after SoftBank made its Carbon Neutral 2030 Declaration, there’s been a growing need for evaluation criteria that includes ESG factors, including environmental considerations.

In the process of carrying out purchasing operations for several thousand suppliers each year, it’s a challenge to introduce new operational procedures in line with the Net Zero policy and to request cooperation from each individual supplier. In light of this, at the Group Synergy Promotion Department we’re taking the lead in drawing up roadmaps to achieve Net Zero. We’re also explaining the situation to suppliers, and conducting surveys. After establishing an overall framework, we first spoke with suppliers with large transaction volumes about specific measures. Responding to third-party evaluation organizations and collecting the information needed for evaluation are also important for understanding our company's activities in an objective way.

Working with suppliers to carry out improvement activities

We’ve been updating our basic procurement policy and supplier code of conduct from an ESG perspective, and in FY2023 (the fiscal year ended March 31, 2024) we established our “Guidelines for Reducing Greenhouse Gas Emissions in the Supply Chain,” which outlines our basic approach to promoting Net Zero.

Using these guidelines, we requested the cooperation of our suppliers and introduced ESG criteria into our annual supplier survey. We incorporated items related to ESG in a broad sense – we’re not just focusing on whether the products and services are environmentally friendly, but also looking at compliance with laws and regulations, respect for human rights, and ethics. This has allowed us to identify numerous issues. For suppliers identified as high-risk, we ask them to develop corrective action plans, and we collaborate on improvement activities.

When we first introduced the supplier survey, the response from suppliers was not so positive. Regardless of industry sector or company size, we often received inquiries that needed to be resolved before we could ask them to respond to our survey. We think that even though they understood the necessity of the survey, the fact that it was something that would also involve the suppliers themselves had not yet sufficiently sunk in. After spending several years holding repeated dialogues and explanatory meetings, we feel the mindset has changed across the entire supply chain.

Telecommunications industry working with suppliers to forge win-win relationships

In our previous efforts, we focused on approaching key suppliers that cover more than 80% of our buying, but considering the targets we set for 2030 and 2050, we must accelerate and expand the scope of our efforts. To do this, we need to promote the implementation of efficient evaluation systems and solutions.

At our supplier briefing sessions, starting this year we expanded the content to include overall ESG initiatives and solutions available from our enterprise business division. By helping our suppliers understand the purpose of the requested surveys and offering proposals to support the challenging task of calculating greenhouse gas (GHG) emissions, we’re aiming to encourage proactive responses from our suppliers.

We also changed our survey methods and will now be using the platform of EcoVadis, an international sustainable supply chain management evaluation organization. Suppliers answer questions that have been customized according to industry, size and country, and the results are evaluated by experts based on international standards and shared with multiple buyers in the form of a scorecard. Suppliers only need to answer once, and the reliability of the evaluation is another benefit. EcoVadis is being used by an increasing number of companies in Japan and abroad, and SoftBank is actively encouraging participation.

Sato explains the merits of using EcoVadis in a webinar

As we have the same aim in mind, the other major telecommunication carriers in Japan also developed a joint survey form on sustainable procurement. Although they are our competitors, it’s also true that they have many suppliers in common. So the use of a common Self-assessment Questionnaire (SAQ) has reduced the burden on suppliers.

Regular three telecommunication company meeting

Advancing various measures to achieve Net Zero

The Procurement Division’s efforts to achieve Net Zero are still in the early stages.

Based on the results of supplier evaluations using EcoVadis and survey forms, we believe it’s necessary to pay particular attention to companies that are not making progress towards Net Zero and flag ones that have human rights-related issues. As it becomes more difficult to understand the situation when moving up the supply chain to Tier 2 and Tier 3 suppliers, it’s also important to learn about the situation firsthand through supplier audits as time allows.

At the moment, we’re in the phase of investigating and improving the situation with our suppliers, but we also feel the benefits of doing so are not being fully communicated. We’d like to convey that with a more positive message.

In terms of communication, we’d also like to create horizontal connections between companies in the same industry. Although the hurdles to achieving this are high, we think that actively recognizing suppliers and providing opportunities for companies in the same industry to spur each other on could be a way to encourage them to take action.

As is the case in some other countries, there will eventually come a time when we’ll need to consider incentives for suppliers that are actively working on ESG. For this we think we’ll need new evaluation standards that include factors that cannot be easily converted into costs. How can we incorporate these standards into our procurement operations? I'm well aware of how difficult it is to root standards in the workplace, so I'd like to take on the challenge by drawing on my own experience as a buyer and utilize the knowledge I've gained so far.

Related Articles

(Posted on October 25, 2024, Original Article Posted on September 19, 2024)

by SoftBank News Editors