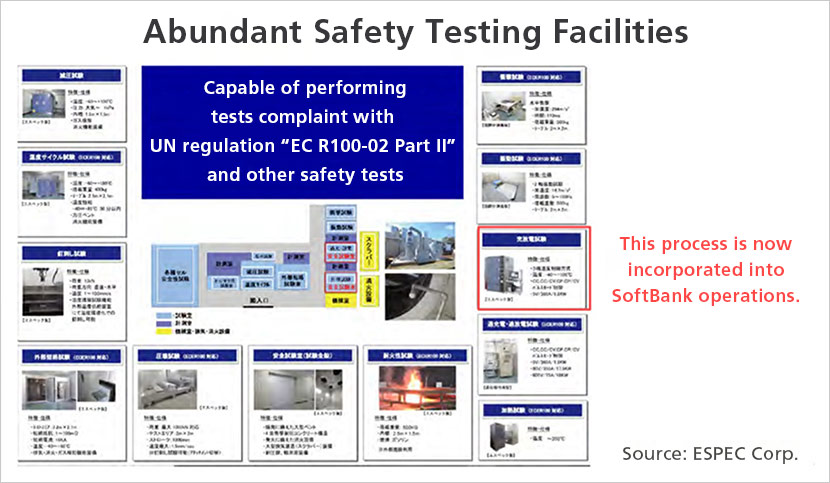

Located in Tochigi Prefecture’s Utsunomiya City, approximately 100km north of Tokyo, the hexagonal complex pictured above is the Battery Safety Testing Center and Utsunomiya Test Center of ESPEC CORP. a world-leader in environmental test chambers.

Anticipating a new device revolution, SoftBank Corp. (TOKYO: 9434) is researching next-generation batteries in a corner of this complex. SoftBank first announced the establishment of this “Next-generation Battery Lab” in March 2021. Now in operation, read on to find out what is happening at the facility and get a glimpse of some advanced technologies on the horizon.

Battery research to ensure high levels of safety and reliability

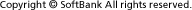

Secondary cells, also called rechargeable batteries, can be used through repeated charging and discharging. Lithium-ion batteries are currently the most commonly used battery type in this area, and expectations for next-generation batteries are high. To support the requirements of constantly evolving devices, future batteries will need to see significant improvements in high-energy densities (i.e., lighter weights), lifespan, safety and cost.

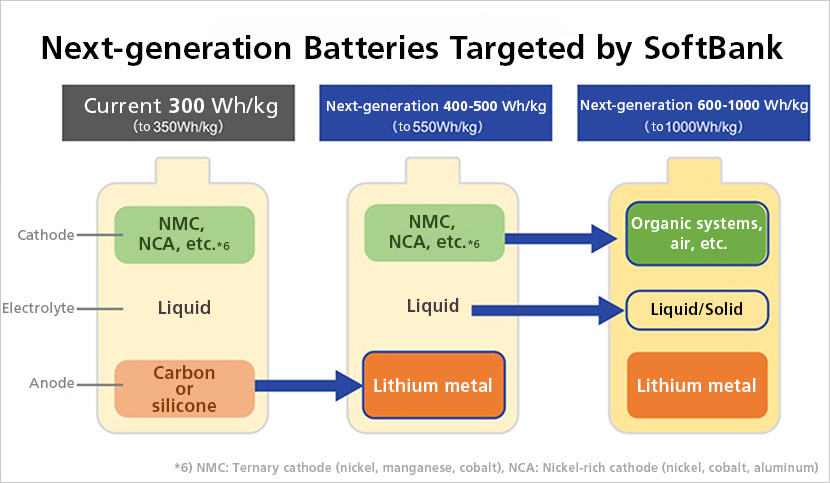

SoftBank’s goal is to develop batteries capable of offering energy (watt-hours) equivalent to current-day batteries but at half their weight; in other words, batteries with a higher specific energy. The SoftBank Next-generation Battery Lab aims to accomplish this by bringing next-generation 400-500Wh/kg (max. 550Wh/kg)-class cells into practical use and achieving higher specific energies in the next-generation 600-1000Wh/kg (max. 1000Wh/kg) class.

R&D on batteries for flying devices in the not-so-distant future

SoftBank’s decision to develop next-generation batteries came largely from its High Altitude Platform System (HAPS) business, as HAPS unmanned aircraft demand lighter, higher-capacity batteries. In general, a battery with a higher capacity means a heavier battery, which in turn means that flying a heavier HAPS aircraft requires more energy. This raises problems, such as being limited to flying at lower altitudes and for shorter durations. On the other hand, the lifespans of batteries for drones and HAPS aircraft do not need to be as long as those for electric vehicles (EVs), averaging 200 cycles (i.e., a cycle being the timespan between charging and discharging) as opposed to 1,000 cycles for EV use. This key difference with EV batteries enabled SoftBank to plan battery development based on a bold R&D strategy—one in which improving specific energy is a top priority. When a longer duration of battery life is achieved, batteries will also be used for smartphones and EVs. SoftBank’s research efforts that began with a focus on batteries for HAPS aircraft have now extended to all manner of flying devices, including small home-delivery drones and drone taxis capable of transporting passengers.

Commercialization of next-generation 400–500Wh/kg-class batteries are not far away

SoftBank is collaborating with US-based Enpower Greentech Inc. to jointly develop next-generation 400-500Wh/kg (max. 550Wh/kg)-class batteries, and both companies successfully tested a 450Wh/kg-class battery. Following further optimization of each battery material component, a 520Wh/kg cell (i.e., the smallest unit of a storage battery) was successfully manufactured. Aiming at commercialization in the near future, “life testing,” in which the degradation of each battery is examined through repeated charge discharge processes, is currently underway.

Battery units

Cell: A component of a storage battery, also called a unit cell

Module: Multiple layers of cells, also called a battery pack

Related press release:

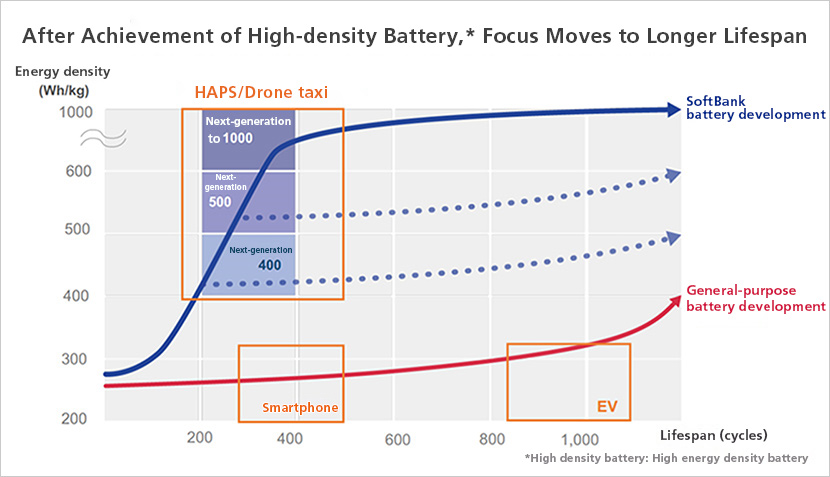

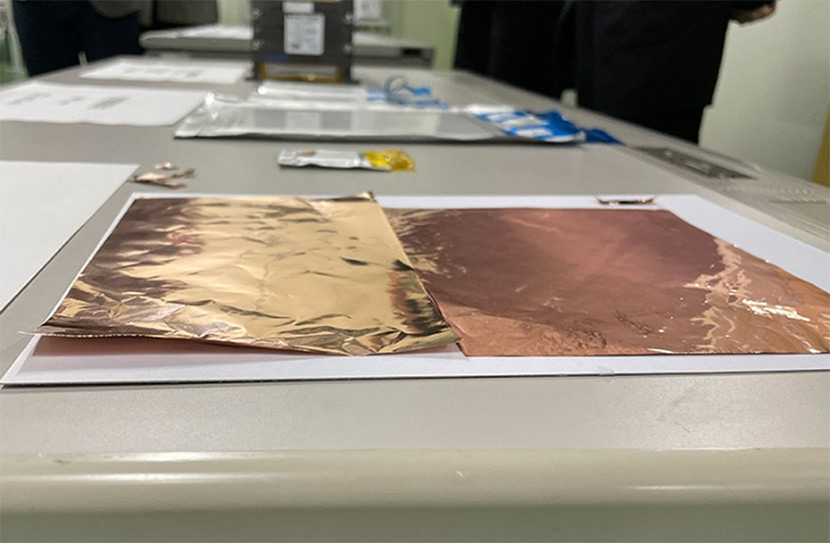

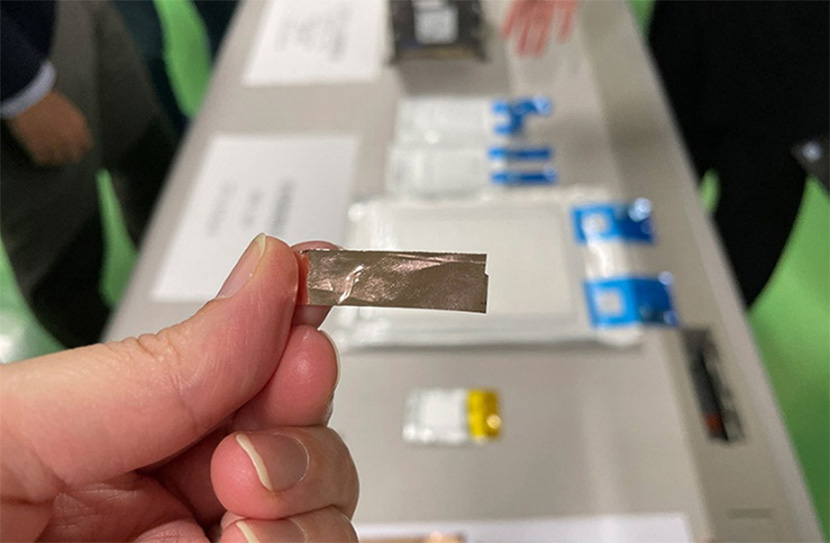

Following the successfully verified manufacturing of a 520Wh/kg cell, achieving the production of next-generation 400-500Wh/kg (max. 550Wh/kg)-class batteries is on the horizon. Meanwhile, SoftBank’s Next-generation Battery Lab is also working to further reduce battery weights, and it is engaging in the development of a “next-generation resin foil,” which could replace existing materials used as the current collector at the anode.

The next-generation resin foil does not appear to be much different than copper foil. However, when held, the difference in weight is staggering, with characteristics somewhat like that of a flaky film. When technologies are realized to put this resin foil into practical use, it is anticipated that batteries will become even lighter and safer.

Next-generation resin foil (left) and copper foil (right)

Research on even more advanced batteries underway

At the lab, there are two more research projects underway. Both initiatives are focused on achieving even higher specific energy.

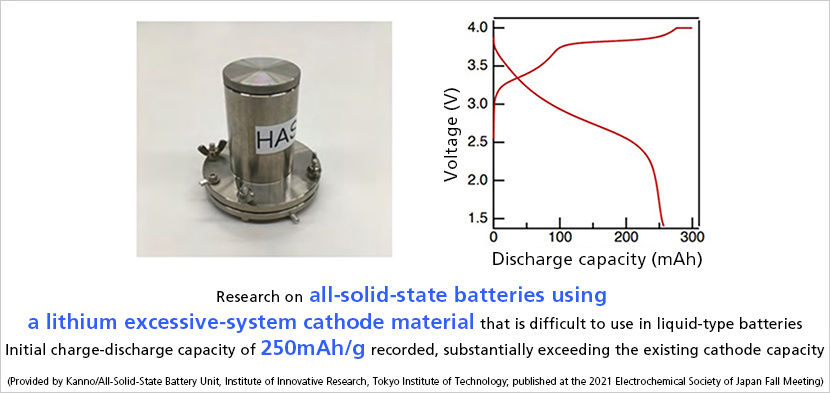

Cathode material for all-solid-state batteries to achieve high specific energy

Liquid electrolytes are currently used in secondary batteries. However, an adverse impact could trigger a fire as liquid electrolytes have a low upper-temperature limit. From a safety perspective, the development of “all-solid-state batteries” that use solid electrolytes will be needed in the future. The Tokyo Institute of Technology and Sumitomo Chemical Co., Ltd. have jointly developed a new cathode material for use with solid electrolytes. This material substantially surpasses the performance of traditional cathode materials.

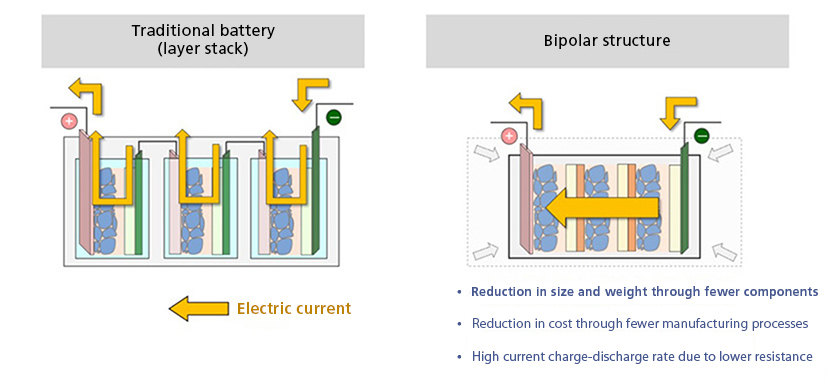

Aiming to achieve 1000Wh/kg with all-solid-state batteries

Solid electrolytes weigh more than their liquid counterparts. On the other hand, the increased level of safety allows a higher voltage to be applied to the electrodes. Furthermore, all-solid-state batteries are suitable for lighter-weight bipolar structure. As such, the arrival of more-advanced batteries is highly anticipated.

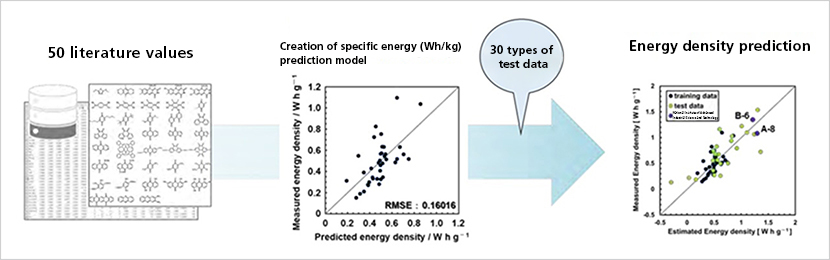

Developing a performance model for organic cathode material

In order to realize next-generation 600-1000Wh/kg (max. 1000Wh/kg)-class batteries, it is believed that organic materials—not the currently used rare materials—should be used for cathode materials. However, apparently, the number of materials capable of being used amounts to the 60th power of 10 (i.e., 1 decillion, or fourth power of 1 trillion), which means it is difficult to identify the best materials out of the available candidates. In a joint research project between SoftBank and Keio University, a predictions model was created so that highly accurate results could be obtained using a limited amount of experimental data. As a result, organic materials that can enable the achievement of a specific energy of 1000Wh/kg were identified. In the future, by combining those materials, research initiatives will turn to studies for the manufacturing of batteries.

SoftBank’s Next-generation Battery Lab is the place to gather cutting-edge next-generation batteries from around the world

SoftBank’s Next-generation Battery Lab is carrying out research and development with the aim of realizing achievements in 10 to 20 years’ time. Inside, lines of devices as tall as adult humans are operating, making rumbling noises. This is a charging-discharging testing facility for batteries. Next-generation batteries made by different manufacturers are brought here so their performance can be evaluated.

15 constant-temperature reservoirs installed as of December 2021

The testing facility generally consists of three types of equipment: a “constant-temperature reservoir,” which is a silver box that looks like an industrial refrigerator, a “charger-discharger,” and an “electrochemical measuring system,” the latter two of which are connected to the constant-temperature reservoir by cables.

| Constant-temperature reservoir | This constant-temperature reservoir is equipped with internal temperature control and capable of evaluating batteries made by different manufacturers under the same conditions. It can also perform assessments at different temperatures, as battery performance can vary depending on the temperature. Furthermore, it is equipped with gas and heat detectors to ensure safety in the event of a fire or other incident. |

|---|---|

| Charger-Discharger | This equipment is used to pass an electric current through the batteries placed inside the constant-temperature reservoir. SoftBank’s Next-generation Battery Lab uses different charger-dischargers depending on the voltage and current being tested. |

| Electrochemical measuring system | This system performs detailed analyses of conditions inside the batteries, such as measuring the resistance value. |

While individual manufacturers publish information on the performance of their batteries, it is difficult to make a fair one-to-one comparison using those figures as many tests are commonly recorded under different environmental conditions; often when a battery is performing at its best. It is therefore imperative that all batteries are evaluated under the same environmental conditions.

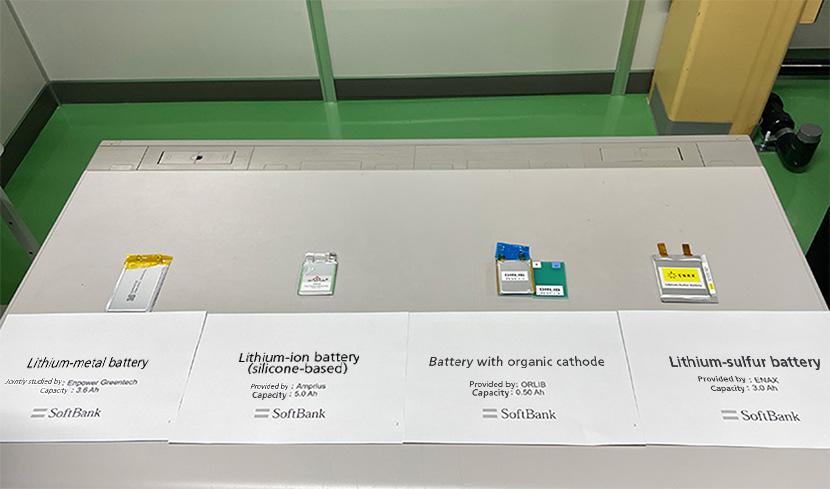

Example of some next-generation batteries evaluated

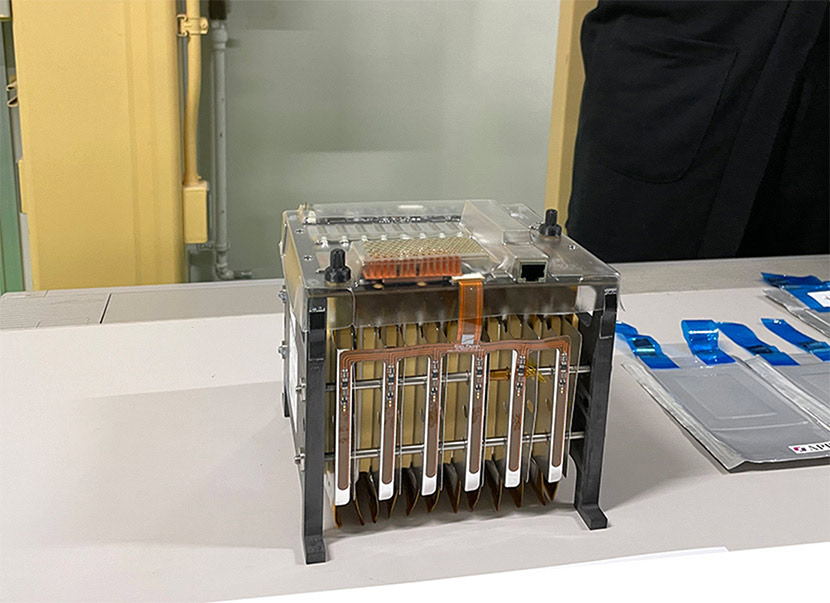

The inside of the constant-temperature reservoir looks like this when cells (i.e., the smallest unit component of a storage battery) are loaded for testing. Up to eight cells can be tested at the same time.

Lifespan testing being conducted for a 520Wh/kg battery of Enpower Greentech Inc.

Actual cell is fixed between the brown boards

Charge-discharge testing process is performed in-house to speed up R&D

While increasing density is prioritized in the development SoftBank’s next-generation batteries, a long lifecycle is one of the key factors required for commercialization. There are many processes in battery development, including testing and certification, that take a long time before a product can be marketed. Therefore, aiming to reduce the time required for development, SoftBank chose to take full control of charge-discharge testing, which is an important point in the development process. Accumulating know-how on battery sets, among other components, has also helped speed up development.

Additionally, a high level of safety is required for commercialization as lithium-metal batteries have been connected to a series of fire accidents in the past. Through collaboration with ESPEC, which has excellent facilities and technologies for evaluating the safety and reliability of batteries, SoftBank hopes to further increase efficiency in development processes.

In the future, the lab is planning to enhance its facilities so that it can perform tests on units larger than cells, such as battery packs and modules. Additionally, by taking advantage of the strengths possessed by ESPEC as a leading manufacturer of environmental testers worldwide, there are plans to embark on the joint development of equipment that can replicate the environmental conditions of the stratosphere, which is relevant to SoftBank’s HAPS business.

Lithium-metal battery module

(Posted on February 9, 2022; Original article posted on December 8, 2021)

by SoftBank News Editors