Promotion of a Recycling-oriented Society

Our approach

to a circular economy

We position the promotion of resource circulation as a key management issue, advancing waste reduction and resource recovery through the efficient use of limited resources. These efforts not only mitigate environmental impact but also enhance our corporate trustworthiness and competitiveness, leading to long-term value creation.

We are committed to reducing, reusing and recycling industrial waste to contribute to the realization of a circular economy.

Initiatives for promoting

a circular economy

in business operations

Reduce

We strive to reduce the amount of paper resources used in the sales of mobile information devices by making individual packing boxes smaller, converting instruction manuals and other bundled documents to applications, and utilizing iPads in our stores.

Moreover, to replace the conventional paper-based invoices, we launched an “online charges guide” starting with the October 2006 statement which allows users to view electronic billing statements over the Internet from a SoftBank mobile telephone or PC. This is provided as a basic service to all individual subscribers.

Reuse

We efficiently collect and resell mobile phones that we have sold or rented to customers. With the domestic and global used smartphone markets growing in recent years, we will continue to enhance our value-added services in line with the diversification of customer needs and respond to market demand.

Recycle

As a member of the Mobile Recycle Network (MRN), an organization which engages in mobile telephone and PHS recycling activities, we promote the collection of used mobile telephone handsets, battery packs, chargers, USIM cards, and other items.

In order to promote collection of handsets, we are establishing collection points for corporate customers and investing in the creation of an environment to promote collection of handsets (e.g., purchasing and installing special equipment) at our directly operated and agent SoftBank stores and Y!mobile stores. Additionally, we have set up operations for collection by specialized companies to further promote these efforts. To make customers feel at ease and encourage cooperation with recycling efforts, mobile telephone handsets are processed for recycling by being physically destroyed with a “mobile telephone punch” during collection. In FY2024, through our collection initiatives, we collected 2.63 million used mobile phones, totaling 417 tons, for reuse and recycling. Having achieved our initial cumulative target of 12 million units (from FY2020 to 2025) ahead of schedule, we have revised our goal for FY2025 to a new cumulative total of 14 million units for the same period. We will continue striving to further increase the volume of collected devices. Additionally, we have achieved, as of March 2024, the goals set by the GSMA (GSM Association), an organization comprising global telecommunications operators, of more than 20% of the number of recycled handsets collected relative to the number of new handsets sold and 100% of the number of collected handsets to be processed without incineration.

Going forward, to further increase the number of devices collected, we will actively promote our recycling initiatives to business partners and customers. In addition, we will strengthen collaboration with MRN and other organizations, placing greater emphasis on sharing information related to the reuse and recycling of used mobile phones.

Overall picture and key points of the value chain for our mobile handsets (PDF: 152KB/1 page)

Initiatives for resource circulation in mobile phone services

Tracking of Waste Electrical and

Electronic Equipment Generated from Sold Products

Waste electrical and electronic equipment (WEEE) generated from sold products is managed using device identification numbers such as IMEI to ensure proper reuse and recycling. All devices collected through our recovery initiatives are 100% recycled or reused.

| Information Tracked by Our Company |

|

|---|

Implementing educational activities to teach about recycling

We hold “Risaikuru” environmental classes for children to learn the importance of recycling through the experience of disassembling cell phones at SoftBank shops across Japan. The class is designed for children to learn about the structure and materials of cell phones by actually disassembling them, and by using the disassembled parts to make crafts, to exercise their creativity and acquire knowledge about recycling while having fun. More than 1,400 people have participated in the class from April 2018 to the end of March 2025.

In addition, environmental classes are held at SoftBank shops nationwide, open to all customers regardless of whether they have a contract with us.

Initiatives for resource circulation

in corporate activities (offices, etc.)

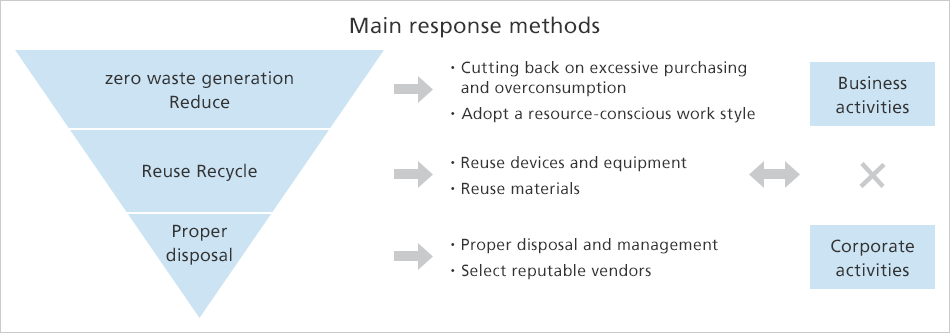

We place 3R (Reduce, Reuse, Recycle) activities, green procurement and paperless initiatives at the core, and continuously promote effective resource utilization and reduction of environmental impact. We also promote awareness and collaboration among all employees, realizing sustainable office operations through legal compliance and technological innovation.

Implementing 3R activities

at the office

Reduce

| Zero Paper for Internal Operations Declaration | Since April 2012, SoftBank has advanced a “Zero Paper for Internal Operations Declaration” and has been proactively promoting a shift to paperless operations for all paper used in internal and external procedures as well as paper used in reports and meetings, etc. Also, in April 2021, we launched the “Digitalization of Stamping Project” to further promote paperless operations. |

|---|---|

| Achieving “100% paperless” operations in the customer support center | To eliminate the risk of information leaks due to the removal of printed media, individual operations which used a large volume of paper including manuals, memos, and notices were identified and improved to achieve “100% paperless” (zero paper usage) operations within the Customer Support Center which handles private customer information. As a result, annual paper usage has been reduced by 3.12 million sheets (equivalent to 240 tree logs) compared to previous years. |

Reuse

| Introduction of reusable plastic cups | In the drink corner at the Takeshiba headquarters, we have introduced reusable bioplastic cups. Without using petroleum-derived ingredients, we have adopted a highly environmentally friendly material made primarily from biodegradable bioplastics*1 that is dishwasher-safe. After use, it can be reprocessed into new products, creating a comprehensive resource circulation system from reuse to recycling |

|---|

- [Note]

-

- *1This plant-derived plastic is produced by chemically synthesizing lactic acid, which is obtained through the fermentation of starch from corn or sugarcane juice. It can ultimately be broken down into water and carbon dioxide by microorganisms.

- *1

Recycle

| Secured recycling box for collecting confidential documents | Instead of individually processing unnecessary documents as wastepaper, they are collected in a special locked security box for collecting confidential documents and batch dissolved at a later date to ensure security and recycling as toilet paper. |

|---|

Appropriate use

of water resources

We recognize that water is both necessary for our business activities and an important resource for the local communities in which our business sites are located. Accordingly, we are addressing water risk and promoting the efficient use of water resources on a companywide basis.

The Environment Committee effectively manages water risk while conducting managerial supervision that ensures both companywide response to these risks and efficient water resource utilization.

Reducing energy and paper consumption through

White Work Style

SoftBank is engaged in reducing environmental impact through the application of information and communications technology (ICT). Through the implementation and proposal of a new way of working called White Work Style, work efficiency is improved while the volume of paper and energy consumed in day-to-day business is also reduced.

White Work Style is a service that allows employees to access internal work systems and software simply by connecting to SoftBank's network. Home PCs or personal iPhones and iPads can also be connected to an environment equivalent to the office PC, allowing flexibility in working time and location, such as teleworking from home, when on the move or from outside of the office.

Furthermore, with computer processing carried out on network servers rather than individual computers, computer power consumption can be reduced. By centralizing these servers at a large-scale data center, operational efficiency can be improved and overall power consumption will be reduced.

According to estimates by the Ministry of Internal Affairs and Communications, energy consumption from the use of office automation equipment and lighting can be reduced by 43% with the introduction of telework. Even when energy consumption at the home office is factored in, it is possible to reduce energy consumption by 14%. Through the promotion of teleworking, it is possible to reduce the amount of energy consumption throughout society. It is also an important initiative from an energy conservation standpoint.

Moreover, through the use of iPhones and iPads, documents stored on servers can be accessed as necessary. This has made it possible to reduce paper handouts and to present information in a more effective manner using video.

Pollution prevention measures

We monitor, manage, and analyze the status of waste generation throughout the organization, and manage waste for optimal disposal and reuse practices. Based on the analysis results, we develop plans to reduce waste generation and continually implement, evaluate, and improve waste reduction plans. Through these efforts, we aim to achieve contributions to the environment and society, such as reducing environmental impact and complying with regulations and ordinances.

In addition, to reduce the amount of waste generated, we collaborate with various valuable item purchasing companies. Before disposing of unused items, we consult with them for assessment and strive for smooth communication, aiming to establish a system where items can be sold as valuable assets.

Processing industrial waste

in the appropriate manner

Industrial waste generated by our business activities is properly disposed of in accordance with the Industrial Waste Disposal Law, and we are committed to preventing pollution.

| Network center | We aim to reduce the final disposal volume of unneeded telecommunication equipment and construction waste by reusing them. |

|---|---|

| Offices and distribution centers | Asbestos used in our offices and facilities has been investigated and countermeasures have been taken to ensure that it is at a level that does not affect human health, and we are systematically improving and removing it. In addition, we are working to complete the treatment of polychlorinated biphenyl (PCB) within the deadline set by the Ministry of the Environment. |

Raising awareness about industrial waste disposal

Employees involved in industrial waste management are provided with practical e-learning training on appropriate waste disposal and electronic manifest systems, ensuring compliance with relevant laws and proper handling. In FY2025, the participation rate for the industrial waste e-learning training for personnel in charge of industrial waste disposal divisions was 100%. In addition, support systems such as consultation desks have been established.

Amount of industrial waste

| Item [Unit] | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 |

|---|---|---|---|---|---|

| Amount of generation [t] | 6,313 | 6,196 | 6,398 | 6,696 | 6,604 |

| Amount of final disposal [t]*1 | 831 | 528 | 557 | 301 | 256 |

Additional resource and waste data can be found under “ESG Data”.

SoftBank achieved a 96% landfill diversion rate in FY2024*2.

Industrial waste diversion rate Verification Report (PDF: 176KB/1 page)

- [Notes]

-

- *1The calculation method has been changed from FY2020.

- *2Rate of waste recycled instead of being landfilled (final disposal)

- *Group companies included in the boundary vary from period to period. Coverage based on the sales ratio of each group company in FY2023 is 99.5%.

- *Third-party verification has been obtained for the amount of final disposal as well as for the waste diversion rate (Limited level of assurance in accordance with ISAE 3000 provided by the Japan Quality Assurance Organization (JQA))

- *Although we anticipate an increase in waste and final disposal volume due to business expansion, we have set targets, as a long-term goal for FY2030, to maintain the current level of waste and final disposal volume through promoting recycling and collaborating with supply chain partners and waste disposal operators.

- *1

Other resource circulation initiatives

Promotion of

plastic resource recycling

One of the value creations of our material issues is promoting a recycling-based society (circular economy). As a KPI, we aim to improve the recycling rate of industrial waste, including plastics, by 1% annually.

To reduce plastic emissions and promote recycling, we are checking the status of plastic use in the value chain, identifying plastic waste emissions, and promoting reuse and recycling before disposal.

Additionally, we collect mobile phones, smartphones, broadband routers, and other devices to support plastic recycling efforts.

Promotion of green purchasing

As part of our green purchasing, since July 2004 we have, in principle, switched copy paper to recycled paper products compliant with the Green Purchasing Law. Furthermore, for stationery items we display on our procurement website the acquisition status of environmental labels—such as Green Purchasing Law compliant products and Eco Mark items—to encourage the purchase of products with lower environmental impact.

Initiatives by our group companies

| SB C&S Corporation | SB C&S Corporation designs and develops computers and mobile peripherals through eco-design, reducing resource use via miniaturization and weight reduction, and promoting component reuse and recycling by adopting easy-to-disassemble structures. Additionally, as part of its ICT equipment sales, SB C&S Corporation operates an ‘ICT Lifecycle Service’ that purchases unwanted devices. Purchased devices are reused and recycled for environmental considerations*1, reducing waste output and repurposing them as valuable global resources and socially circulating items. |

|---|---|

| ASKUL Corporation | In April 2022, ASKUL Corporation launched the “ASKUL Resource Circulation Platform” to promote resource circulation by collaborating with all stakeholders across the value chain throughout the entire product lifecycle—from planning and design to manufacturing, sales, reuse, and ultimately resource recovery and product re-commercialization. To make effective use of limited resources and reduce CO2 emissions, participants are asked to return used clear folders, which are then recycled and remanufactured. |

| ZOZO, Inc. | ZOZOTOWN offers trade-in programs—“Kaikae-Wari”*2 and “Itsudemo Kaikae-Wari”—that allow customers to trade in items they previously purchased. Amid growing concerns about fashion waste, these services help build a circular system within ZOZOTOWN by reselling trade-in items in the pre-owned apparel section, ZOZOUSED. Items that do not meet ZOZOUSED's resale standards are sold to multiple clothing recyclers that follow proper disposal practices. Going forward, we will continue to promote a circular economy based on a sustainable model. |

- [Notes]

-

- *1The recycling rate for desktop computers is approximately 99.6%.

- *2“Kaikae-Wari” is a registered trademark of ZOZO, Inc.

- *1