Supply Chain Management

SoftBank will continue to develop together with our suppliers.

SoftBank has always chosen suppliers that share our vision toward social contribution, working together to create innovative services offering new lifestyle propositions.

“We foster relationships of trust based on mutual understanding, and improve by learning from each other for the benefit of our customers.”

“We maintain fair relationships with suppliers and provide an environment where customers can choose quality products and services with confidence.”

“We share a passion for contribution to society through our products and services, and pursue innovation together with our suppliers.”

SoftBank evolves together with its suppliers.

Basic policy

Procurement Policy

In order to maintain fair and positive relationships with suppliers, the Procurement Policy of SoftBank Corp. stipulates the following eight items: “provision of fair opportunities for competition,” “selection of suppliers based on rational and clear criteria,” “compliance with laws,” “management of confidential information provided by suppliers,” “mutual confidence-building with suppliers,” “environmental conservation,” “prohibition of mixing private relations,” and “CSR efforts.” All procurement activities conducted by the Procurement Department are carried out in accordance with these basic policies.

Supplier ethics and rules of conduct

In order to deal with CSR-related issues together with suppliers, provide reliable and safe products and services to customers, and conduct business activities which are trusted by society, we have established the “Supplier Ethics and Rules of Conduct” and request that all suppliers comply with these rules.

The “Supplier Ethics and Rules of Conduct” includes 14 items which consist of “Concern for the environment,” “Information security,” “Fair competition,” “Ensure quality and safety,” “Consideration for Human Rights,” “Occupational safety and health,” “Prohibition of child labor,” “Prohibition of forced labor,” “Prohibition of discrimination and inhumane treatment,” “Working hours,” “Fair payment,” “Freedom of association,” “Responsible mineral procurement,” and “Coexistence with local communities.”

Green procurement guidelines

Moreover, to contribute to the sustainable development of society, we have established the “Green Procurement Guidelines” which indicate our fundamental approach to green procurement for all of our suppliers.

These guidelines are in accordance with the contents of the “Ecology Guideline for the ICT Industry,” which was formulated by the ICT Ecology Guideline Council* in response to the proposal by the workshop concerning the ecological response in the information and telecommunications field hosted by the Ministry of Internal Affairs and Communications.

Our goal in establishing these guidelines is to promote the procurement of products which contribute to the reduction of CO2 emissions.

We highly value the voluntary and proactive proposals from our suppliers and will engage in business activities with an environmental emphasis by engaging in environmental conservation activities together with the suppliers.

- [Note]

-

- *

Council inaugurated on June 26, 2009, by the Telecommunications Carriers Association, Telecom Services Association, Japan Internet Providers Association, Communications and Information Network Association of Japan, and the ASP-SaaS-IoT Cloud Consortium (ASPIC) to raise and further promote measures to prevent global warming in the industry

- *

System

The General Manager of the Finance & Controlling Cost Management Division, an executive officer in charge of the Purchasing Department, is responsible for this division. In order to properly manage the supply chain in accordance with the above policies and guidelines, the Procurement Department regularly discusses with each department to ensure prompt coordination among the departments. The ESG Committee (Chairman: Junichi Miyagawa), established as an advisory body to the Board of Directors, oversees the activities of the Supplier ESG Program in order to enhance supply chain sustainability. The FP&A and Procurement Division, Finance Unit reports to the ESG Committee on supply chain sustainability procurement activities as necessary, and the committee deliberates on issues and responses.

Supply chain strategy

Responsible procurement activities

With the management philosophy of “Information Revolution, Happiness for everyone”, We aim to be a lifestyle company that makes people's lives richer and more enjoyable. In order to achieve this goal, we have established a procurement policy to maintain fair and good business relationships with our suppliers. This procurement policy is important not only for achieving our management philosophy, but also for managing procurement costs, quality, delivery time, and supply stability. Based on this policy, we have identified the following five items as particularly important in our supply chain strategy: 1) Provision of fair opportunities for competition, 2) Selection of suppliers based on rational and clear criteria, 3) Compliance with laws, 4) Management of confidential information provided by suppliers, and 5) Green procurement. In addition, in order to promote responsible procurement activities, we have set the following two items as important ESG targets.

Respect for human rights and ensuring occupational health and safety

We have established the “Supplier Ethics and Rules of Conduct” in order to carry out corporate activities that are trusted by society together with our suppliers.

The Rules of Conduct stipulates such items as the prohibition of child labor and forced labor, the prohibition of discrimination and inhumane treatment and the reduction of excessive working hours, as well as the improvement of the working environment for employees. Suppliers are strictly committed to complying with the Rules of Conduct.

Environmental action guidelines

for suppliers to address

climate change

and

green procurement guidelines

for suppliers

From the perspective of global environmental conservation through our business activities, we have established the Environmental Action Guidelines and the Green Procurement Guidelines, which aim to promote the introduction of products that contribute to reducing CO2 emissions and are promoting environmentally friendly procurement activities.

Supply chain

Supply chain overview

SoftBank's supply chain is spread across various countries and regions around the world; in fiscal year 2023, the supplier spending ratios by region are 49% in Japan, 40% in the Americas, 7% in Europe, and 4% in Asia. In addition, by category, supplier spending ratios are 42% for devices, 33% for service and construction, 16% for equipment (and maintenance), and 9% for others.

Supplier selection

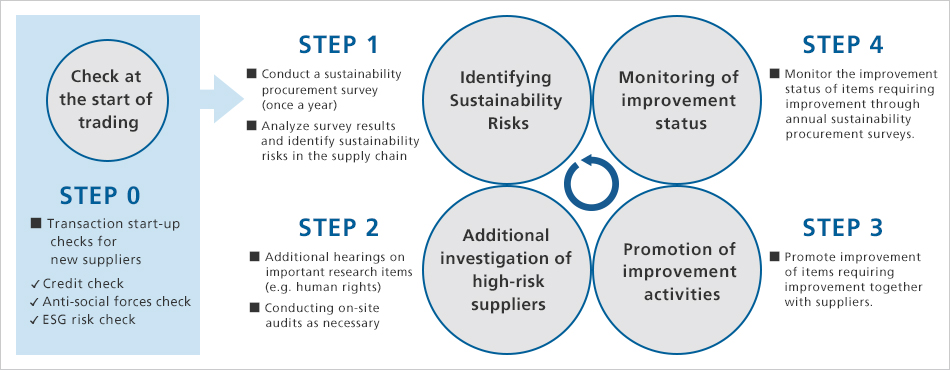

When selecting suppliers, we evaluate suppliers in terms of quality, price, delivery, supply stability, reliability, etc., and conduct business with suppliers that meet minimum standards, while conducting ongoing supplier risk assessments, including sustainability perspective. We reduce risks within the supply chain by establishing a PDCA cycle, which includes the establishment of the Supplier Ethics and Rules of Conduct, conducting Sustainability Procurement Survey, evaluating suppliers and identifying issues, and conducting supplier inspections and audits. In addition, when starting a new transaction with a supplier, we evaluate and select the supplier in accordance with our purchasing rules, and conclude a basic transaction agreement that includes the supplier's compliance with our Supplier Ethics and Rules of Conduct. ESG aspects of environmental, social and governance are included and applied a certain weight to the supplier evaluation for telecommunications and IT equipment procured for use in the services we provide, as well as for some facility equipment installed as part of our telecommunications infrastructure.

To promote sustainability initiatives by suppliers, we share the results of sustainability risk assessments and introduced EcoVadis in FY2024 to create an environment where suppliers can reference outstanding initiatives, including comparisons with other companies. Suppliers identified as high-risk suppliers are asked to prepare corrective action plans. If a supplier does not meet the minimum ESG requirements through audits, etc., we will recommend corrective actions and encourage continuous improvement If we do not confirm that the supplier has presented remedial measures to correct serious nonconformities within 90 days, we will consider discontinuing the use of that supplier after making a comprehensive judgment, taking the business into consideration.

Significant suppliers

Relationships with various suppliers are important when it comes to conducting business activities.

We have more than 2,000 suppliers around the world, and in our supply chain management, we identify important suppliers from the perspective of transaction volume, substitutability and ESG aspects of environmental, social and governance and conduct appropriate supply chain management as an important supplier which cover the top 80% or more of the previous year's purchases among a wide range of suppliers.

Criteria for selecting significant suppliers

| Suppliers of key products | Suppliers that handle key products and components such as radios, base stations and networks that support the core domestic telecommunications business (mobile and fixed-line businesses). |

|---|---|

| Non-substitutable Suppliers | Suppliers that can not be substituted (in view of the fact that there are essentially no substitute products on the market, or that a long-term disruption of the supply chain would critically damage the core business). |

| Suppliers with High Transaction Volume | Suppliers that have transactions above a certain amount. |

| Suppliers with low sustainability risks | Excellent ESG aspects of environmental, social, and governance, with no risks identified by region, sector, or procurement category. |

Building a sustainable supply chain

Sustainability procurement survey

We conduct an annual sustainability procurement survey of our significant suppliers in order to identify potential “sustainability risks” in our supply chain and take appropriate measures. We believe that in order for suppliers to achieve better ESG performance, it is important to understand examples of other companies, therefore we evaluate survey results and provide feedback, including comparisons with other companies.

Responsible sourcing of minerals

In order to fulfill our social responsibility in our purchasing activities, we are working with our suppliers to eliminate the use of products containing conflict minerals.

Specifically, our Supplier Ethics and Rules of Conduct stipulates that we do not use tantalum, tin, tungsten, or gold, which are sources of funding for rebel groups that commit human rights abuses in the Democratic Republic of Congo and its neighboring countries, and we require our suppliers to comply with this stipulation.

Survey results

In fiscal 2020, we conducted a survey of primary suppliers on the country of origin of conflict minerals contained in their products using the Conflict Minerals Reporting Template (CMRT*1) and received responses from 17 companies.

| Survey Results | Gold (Au) | Tantalum (Ta) | Tin (Sn) | Tungsten (W) |

|---|---|---|---|---|

| Total number of refineries for each metal |

156 (Of which, 2 companies are in the target country*2) |

38 (No target countries) |

87 (Of which, 2 companies are in the target country*2) |

49 (No target countries) |

- [Notes]

-

- *1

CMRT (Conflict Minerals Reporting Template): A survey format for reporting conflict minerals provided by the Responsible Mining Initiative (RMI), which has established international guidelines on conflict minerals.

- *2

Target Countries: This refers to the Congo and a total of 10 countries designated as target countries for conflict minerals: Angola, Zambia, Tanzania, Uganda, South Sudan, Rwanda, Central African Republic, Republic of Congo and Burundi.

- *1

Positioning with materiality

Our materiality is linked to (4) Contributing to the global environment through the power of technology and (6) Developing a resilient management base, and we are working throughout our supply chain to contribute to solving global CSR issues together with our wide range of suppliers. We are working with a wide range of suppliers throughout our supply chain to help solve global CSR issues.

Efforts toward sophistication

Collaborate with other companies by participating in related initiatives

We are a member of the Supply Chain Subcommittee of the Global Compact Network Japan (GCNJ), and are working with companies in various industries to share practical issues related to social and environmental problems, including human rights abuses in supply chains, and to produce outputs to support their resolution, with the aim of promoting sustainable supply chain management in a wide range of industries. We have announced collaboration among telecommunications carriers on sustainable procurement with Nippon Telegraph and Telephone Corporation and SoftBank Corp. to hold regular meetings and create a common SAQ for the telecommunications industry to standardize questionnaires on sustainability and reduce the burden on our suppliers.

In FY2023, we introduced SAQ*1 common to the three companies (NTT, KDDI, and SoftBank), and in FY2024 EcoVadis*2, a third-party evaluation platform to further strengthen engagement with suppliers.

In FY2024, we will publish a handbook that introduces our sustainability initiatives, our approach to sustainability, our own CO2 emissions measurement, and other initiatives that we would like our suppliers to implement, and we will support our suppliers' activities to improve sustainability in their supply chains.

- [Notes]

-

- *1

Sustainability questionnaire standardized by NTT, KDDI, and SoftBank in FY2023; SAQ identifies items such as environment, human rights and labor, health and safety, fair trade and ethics, quality and safety, and information security to be shared between buyers and suppliers regardless of industry Structure.

- *2

Sustainability assessment service consisting of four parts: Environment, Labor Practices and Human Rights, Ethics, and Sustainable Sourcing.

- *1

Declaration of Partnership Building

In support of the aims of the “Conference on Promoting Partnership Building for the Future,” whose members include the Chairman of Nippon Keidanren, the President of the Japan Chamber of Commerce and Industry, the President of the Japanese Trade Union Confederation, and relevant ministers (Cabinet Office, Ministry of Economy, Trade and Industry, Ministry of Health, Labor and Welfare, Ministry of Agriculture, Forestry and Fisheries, and Ministry of Land, Infrastructure, Transport and Tourism), we have released a “Declaration of Partnership Building”.We aim to build new partnerships by promoting collaboration, co-existence and co-prosperity with our supply chain partners and businesses that create value. In making this declaration, the following individual items are specified.

- We will improve operational efficiency with related business partners through information sharing and visualization of the entire supply chain.

- By promoting operations through an electronic transaction system (Web-EDI), we will promote telework and paperless operations, thereby increasing operational efficiency and strengthening control for both parties.

- We support our own health management practices and provide know-how to our partner companies.

Supplier Engagement

We believe that part of our responsibility for our products and services is not only to provide our customers with an environment where they can select better products and services with confidence, but also to ensure that human rights are respected and a safe working environment is maintained throughout the supply chain, and that an environmentally friendly business environment is also maintained. We regard our suppliers as important partners. We conduct a variety of supplier training and engagement programs throughout the year to strengthen the capabilities of our suppliers, and to ensure the quality of the products and services they provide to us and to improve their environmental, social, and governance performance.

| Item | Target | Contents |

|---|---|---|

| Supplier Training | Significant Suppliers |

|

| Sustainable Procurement Handbook | All suppliers | In FY2024, we published a handbook that introduces our sustainability initiatives, our approach to sustainability, and initiatives that we would like our suppliers to implement, such as measuring their own CO2 emissions, to support our suppliers' activities to improve the sustainability of their supply chains. |

| E-learning (EcoVadis Academy) |

EcoVadis Users |

|

| Supplier Day | Major radio equipment manufacturers |

|

Reduction of greenhouse gas emissions

through the supply chain (Scope 3)

SoftBank Corp. will work to achieve Net-Zero emissions by 2050, which means zero emissions of all greenhouse gases related to our business activities, including not only greenhouse gases emitted from electricity used in our business activities (Scope 1 and 2) but also from our entire supply chain (Scope 3).

Since the overwhelming majority of our products are Scope 3, we need to decarbonize our entire supply chain, and it is essential that we promote this with our suppliers. We have established “Guidelines for Reducing Greenhouse Gas Emissions in the Supply Chain” and will promote purchasing activities to achieve net-zero emissions.

Nature Positive

Our company supports the achievement of “Nature Positive” pursued by the international community and promotes efforts to reduce the impact on biodiversity and address any deforestation associated with business activities, including our suppliers, in order to contribute to its realization.

Establishment of guidelines for procurement activities

in consideration of human rights

For goods, novelties, and promotional items in our sustainability procurement activities, we have established “Guidelines for Human Rights Conscious Procurement Activities for Goods, Novelties, and Promotional Items” and confirm compliance with the guidelines before placing orders.

Electronic trading system

In order to promote purchasing activities, SoftBank Corp. is promoting operations using an electronic transaction system (Web-EDI). EDI* is an electronic exchange mechanism used exclusively between businesses (B to B). In fiscal year 2023, the EDI order placement rate was 90%, and we are working to increase the rate to 90% or higher in fiscal year 2024 and beyond.

- [Note]

-

- *

EDI is an abbreviation for Electronic Data Interchange.

- *

Improving the skills of purchasing managers

In purchasing operations, when negotiating with various suppliers for the purpose of procuring goods, it is required to achieve continuous and stable procurement through fair, equitable and transparent transactions. In order to achieve this goal, we conduct basic training for purchasing staff (e.g., on the Act against Delay in Payment of Subcontract Proceeds to subcontractors) every year, as well as basic training for new purchasing staff, and promote the acquisition of the Certified Procurement Professional (CPP) certification, an external qualification, to improve procurement and purchasing skills. We also provide education on basic knowledge of supplier ESG program for purchasing staff, and we have incorporated goal achievements related to sustainable procurement into personnel evaluations for purchasing staff.